New Technologies

In recent years, H.Q.E has brought new pump technologies to the market to improve efficiency and operational performance.

Below is a comparison between the four main technologies:

1.- PCP Self-insert

2.- PCP Metal&Metal

3.- PMM PCP

4.- Lubricated Transmission System (STL)

STL:

The artificial lift systems and technologies that HQE includes in addition to your PCP are:

1.- Mechanical Pumping

2.- Hydraulic Pumping

WELLHEAD INSPECTION AND PRODUCTION OPTIMIZATION

Real-time inspection, which is performed during trips to the surface of the production pipeline; In order to detect cracks or fissures, losses due to wall thickness or grooved by rod.

SELF-INSERT

It consists of a pump that its assembly (rotor – stator) lowers into the production pipe with the rod string -You do not need to remove the pipe to replace the pump -Can be installed on top of another lifting system. -A WorkOver equipment is not necessary for pump replacement. -The system allows replacing mechanical pumping equipment. -In the self-insertable system you can determine the breaking point of the pipe and take advantage of the rest. -Reduce the rate of pulling and intervention. -Increase the extraction range of subsurface PCP pumps. -Elimination of backspin damage.

METAL-METAL PCP

It consists of a Progressive Cavity Pump in which the stator is made of metallic material. In this way the fluid is pumped through a Metal-Metal type rotor/stator combination. The Metal-Metal Pump is recommended for: Fluids with high viscosity or aggressive chemical conditions (such as H2S and CO2) High GOR (Gas-Oil Ratio) High Temperature and Unconventional Thermal Oil Recovery. Eliminates the gas permeability effect. Hysteresis Reduction in the length of the pumps, facilitating the transportation, installation and handling of the equipment.

PMM PCP

It is the result of the union between the permanent magnet bottom motor and the tubular PCP pump. This union generates the optimization of energy consumption as well as the total efficiency of the system. -Surface Power System & Head -Check and Drain Valves -Power Cable -NETZSCH ESPCP – Pump -Bearing housing -Motor Protector -Submersible Permanent Magnet Motor (PMM) -Background Sensor. -PMM control (Soft start, stop, speed change and direction of rotation) -Display of information on the main engine parameters -PMM Motor Protection -Head Voltage

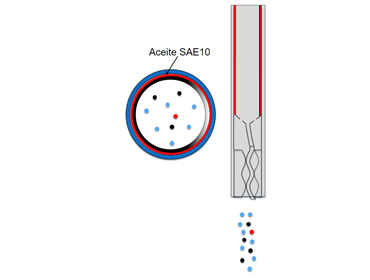

STL

This arrangement consists of a rotating tube or hollow rod within the production pipe. The rotating tube guides the fluid from the bottom to the surface. Between the rotating tube and the production pipe, there is an O-ring type space in which an anti-friction lubricant is injected between the external face of the rotating tube and the internal face of the pipe. MITIGANT EFFECTS -Eliminate loads, reduce combined wear resulting from friction and contact corrosion that originate from wellbore deviations. -Reduce the rate of pulling and intervention. -Reduce the cost per incremental barrel of oil, through the reduction in resistive torque and increase in electrical efficiency.