WELLHEAD INSPECTION AND PRODUCTION OPTIMIZATION

Real-time inspection, which is performed during trips to the surface of the production pipeline; In order to detect cracks or fissures, losses due to wall thickness or grooved by rod.

SCANNEX PIPE INSPECTION

- Eliminates unnecessary transportation to the inspection center -Predicts tube life reducing unexpected downtime -Maximizes the life of the tubes while minimizing investment -Well profile report, which is a great tubular management instrument -Indicates problems that can be directed to the correct areas -Evaluation and historical record of comprehensive tubular management

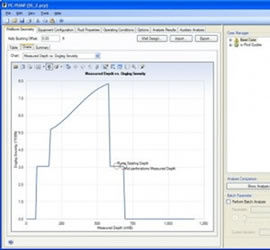

PRODUCTION OPTIMIZATION

For the sizing, analysis, design, evaluation and monitoring of any application of artificial lift projects, allowing the modeling of production systems in order to optimize the useful life of the wells. HQE SAS has established a protocol under methods for identifying failures, performing the analysis, reviewing the behavior and using the methodology applicable to the type of failure that occurs in the PCP system. Review and analysis of operating parameters such as amperage, voltage, RPM, torque, among others, for the identification of failures or anomalies that allow preventing future interventions in ESP, BM, BH and PCP Artificial Lift Systems

RODDEX ROD INSPECTION

- Pittings. - Cross indication. - Corrosion. - Stretching. - Diameter Loss.

CATHODICAL PROTECTION

We stock a wide range of cathodic protection materials from renowned OEMs and maintain alliances with several leading cathodic protection materials manufacturers to provide high-quality materials supply service with appreciable turnaround time. We provide cathodic protection engineering, our strong team consists of experienced and qualified engineers and has a reputation for delivering technical excellence with professionalism.